Marine Equipment Inspection by Japanese Government

THIS PAGE introduces the inspection scheme conducted for statutory marine equipment by Japanese Government / Japanese marine administration (hereinafter referred to "JG), not by ClassNK.

Marine equipment installed, fitted or provided on Japanese flagged ships should comply with the technical standard regulated in Japanese national laws. Each equipmentis to be inspected by JG officers themselves directly.

1. Inspection scape of marine equipment

Marine equipment specified in International Conventions/Code/Regulation (SOLAS, MARPOL and COLREG) is subject to inspection.

Click to enlarge

2. Inspection methods

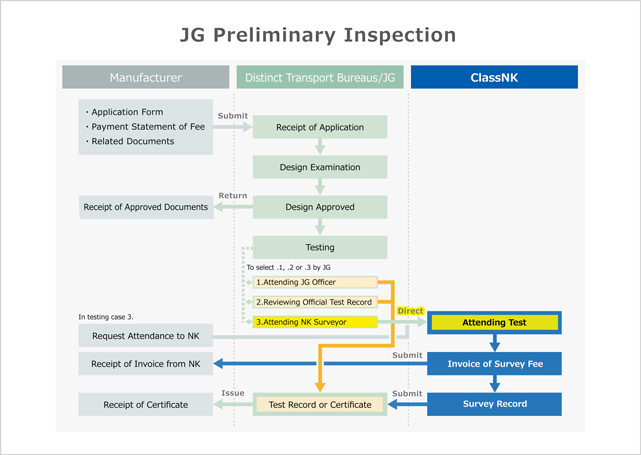

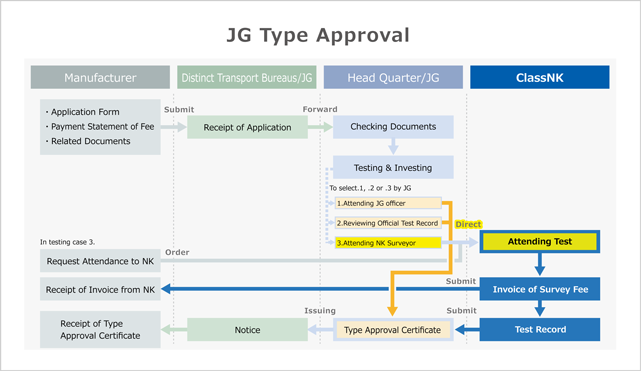

There are two procedures, (1) “Preliminary inspection” applied for per equipment and (2) “Type approval” on the premise of mass production.

(1) For preliminary inspection, design inspection and performance test are required for each one.

(2) For type approval, documents examination, performance test and factory investigation are required for prototype.

Click to enlarge

3. Application of inspection

In case of an overseas manufacturer, the manufacturer is to apply to Kanto District Transport Bureau, which is the representative office of JG in Yokohama, for both preliminary inspection and type approval. At that time, the applicant is to submit an application to the Bureau, accompanying relevant documents below (Preliminary inspection: two sets for each item, Type approval: one set for each item). See Application forms below. When submitting the application, the applicant shall pay for the inspection fee in advance. As for preliminary inspection, the applicant is to apply for the inspection at least two months before the test starting. Besides, as for type approval, the applicant is to consult to the Inspection and Measurement Division, Maritime Bureau (Administration Headquarter of JG) at least six months before submitting the application.

3.1 Preliminary inspection

① Application Form for Preliminary Inspection

② Payment statement of fees

③ Relevant documents

i. Manufacturing specification including performance, shape, structure, materials

ii. Drawing showing the structure, layout

3.2 Type Approval Test

① Application

② Payment statement of fees

③ Attached document

i. Document relating to technical standard conformity of equipment

(a) Manufacturing specification showing performance, shape, structure, and material etc.

(b) Drawing showing constituent and arrangement etc.

(c) Document of the compliance with technical standard (test record/report etc.)

(d) User instruction/operation manual (direction for usage)

(e) Copy of type approval certificate issued by the foreign government in case equipment has already granted type approval from some foreign government, where the applicant intends to utilize the test report.

ii. Document relating to manufacturing capability in factory

(a) Manufacturing process (Flow chart of manufacturing)

(b) Manufacturing records(In the case of no manufacturing records of the equipment, manufacturing records of similar equipment)

(c) Outline and layout of manufacturing factory

(d) Organization chart of a department relating to manufacturing and quality control of equipment

(e) Quality control standard relating to equipment (acceptance inspection of material etc., intermediate inspection at manufacturing process, acceptance inspection of subcontract equipment/purchased equipment, in-house inspection standard for final/finished check at the completion of equipment)

iii. Other documents

(a) Method of marking (name of equipment, model, dimensions, method of use, date of manufacture, serial number, manufacturer and type approval number)

(b) Pamphlet of the equipment

(c) Articles of incorporation

(d) For containers, the assurance from the manufacturer prescribed in Regulation 5, 3. of Annex I to CSC Convention

(e) A copy of the radio equipment type examination certificate issued by Minister of Internal Affairs and Communications, if any

4. Inspection attendance

The attendance of Japanese Government (JG) Inspector (in some special cases nominated by JG, recognized organization (RO) surveyor instead) is mandatory at testing for both preliminary inspection and type approval unlike MED certification scheme. Besides, where attending inspection by RO surveyor is conducted, an additional fee is charged by RO separately.

5. Omission of inspection

As above, in principal, the attendance of JG Inspector is necessary for per product. However, in some cases below, a part or all of the tests are exempted, referred to the official test records/reports.

The test records/reports should be in accordance with test method and criteria specified in international technical standard prescribed by International Maritime Organization (IMO) (the technical standard and criteria based on the law of Japan adopting these method and criteria), and are listed below.

(1) Test reports issued by testing laboratory of Japanese national / local government (incl. incorporated administrative agency) or foreign government

(2) Test report issued by a domestic incorporated foundation/corporate juridical person/nongovernment testing laboratory which have substantial experience of appropriate test and approved based on ISO/IEC 17025 (JIS Q 17025) “General requirements for the competence of testing and calibration laboratories”

(3) Test report issued by a foreign incorporated foundation/corporate juridical person/nongovernment testing laboratory which has substantial experience of appropriate test and approved based on ISO/IEC 17025 (To be test report for equipment which have already been approved by foreign government. As for fire protection materials, it is restricted that the materials are approved by Denmark, Estonia, Greece, Netherlands, Norway, Spain or UK government and test reports are issued by testing laboratory approved by these governments.)

(4) Test reports that Surveyor of registered classification societies (ClassNK is registered) witnessed approval test and signed on test results

6. Others

Manufacturers of Lifeboat, Liferaft and Launching appliance are to consult with JG in advance due to JG requirements at periodical inspection for maintenance. And it is to be considered that there are some special requirements for equipment for only Japanese flagged ships (e.g. Dye Markers).

Related Information

- Application Form for Preliminary Inspection (MARPOL)(Word)

- Application Form for Preliminary Inspection (MARPOL)(PDF)

- Application Form for Preliminary Inspection (SOLAS)(Word)

- Application Form for Preliminary Inspection (SOLAS)(PDF)

- Objective marine equipment of Preliminary inspection

- Objective marine equipment of Type approval